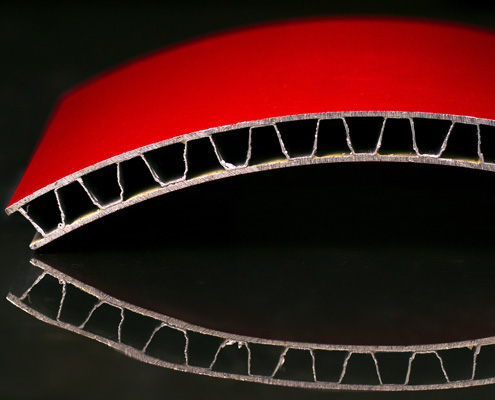

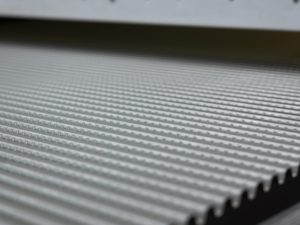

5W Srl produces Honeycomb panels with an aluminum honeycomb core, coated with external skins in aluminum or steel. These panels combine strength, flatness, and certified safety, and are completely non-combustible—making them the ideal solution for those seeking durable, reliable materials capable of ensuring high mechanical performance and fire safety.

Thanks to the ability to customize the internal core, we can adapt the panels to the specific needs of each project by selecting the cell size and density, as well as the thickness of both the honeycomb core and the external skins. This flexibility makes Honeycomb panels suitable for a wide range of applications: from ventilated façade claddings and suspended ceilings to raised floors, elevator walls, the railway sector, and the naval and nautical industries.

In addition, all panels can be further enhanced thanks to their excellent workability and the possibility of being painted or enriched with high-quality finishes such as HPL, laminates, solid surface, or natural and engineered stone—ensuring aesthetics and functionality without compromise.